10 days ago I picked up my 27th Corolla I've ever owned! It's a 1982 TE72 with 267,000km on it. 3TC automatic.

This purchase was justified in my brain by the added duty beyond a daily driver, of being a tool of education, a racing school student car. I'd been giving formal and information racing instruction during our drifting events for years now. For some it was successful for others, not so much. I realized recently what a major differentiating factor was: the cars!

Some students showed up in good working cars, that ran well, and were logically or accidentally setup to drift well. However for a majority of people learning to drift, and supplying their own drift cars, budgets were tight, experience was nearly nil, and they were also on the path of learning to work on cars at the same time of learning to operate them at accelerated rates. These two paths of learning are commonly combined but far from complimentary, let alone affordable! Much of my time giving instruction was spent on tire pressures, tire choices, yelling at people who tell me they don't need a parking brake, and trying to get cars just to idle. "Bro, the clutch only slips a bit!" is not something supportive of a reliable learning experience.

I will continue to believe that drifting is easy, like super easy. What's difficult is getting the opportunity to make safe mistakes in a well setup car in a safe location. These factors change what would be 4 hours to perfect into 2-3 years. lol Seriously speaking, by providing a reliable and consistent experience for students, even if it's only for a few laps, the skills will fruit much quicker. For me instructing, I'm hoping their driving habits and flaws will be much more obvious with a consistent vehicle than trying to diagnosis mid corner if they suck or it's the random new car I'm in.

I decided this was important to me, but our local drifting club couldn't support the idea of funding such a car, so I decided to buy one and do it myself!

Tangerine cost me a whole $400. I had left a note on this car over 5 years ago! Acquired from a lovely music teacher who owned the car for 28 years.

The power steering squealed, the distributor leaked, shocks blown, and the thermostat was stuck open. Otherwise it ran and bumbled around town with the simple clunks you'd expect from an 34 year old Toyota. Remember I said this started only 10 days ago? Yeah, we got cracking.

[caption id="" align="aligncenter" width="1024"]

This purchase was justified in my brain by the added duty beyond a daily driver, of being a tool of education, a racing school student car. I'd been giving formal and information racing instruction during our drifting events for years now. For some it was successful for others, not so much. I realized recently what a major differentiating factor was: the cars!

Some students showed up in good working cars, that ran well, and were logically or accidentally setup to drift well. However for a majority of people learning to drift, and supplying their own drift cars, budgets were tight, experience was nearly nil, and they were also on the path of learning to work on cars at the same time of learning to operate them at accelerated rates. These two paths of learning are commonly combined but far from complimentary, let alone affordable! Much of my time giving instruction was spent on tire pressures, tire choices, yelling at people who tell me they don't need a parking brake, and trying to get cars just to idle. "Bro, the clutch only slips a bit!" is not something supportive of a reliable learning experience.

I will continue to believe that drifting is easy, like super easy. What's difficult is getting the opportunity to make safe mistakes in a well setup car in a safe location. These factors change what would be 4 hours to perfect into 2-3 years. lol Seriously speaking, by providing a reliable and consistent experience for students, even if it's only for a few laps, the skills will fruit much quicker. For me instructing, I'm hoping their driving habits and flaws will be much more obvious with a consistent vehicle than trying to diagnosis mid corner if they suck or it's the random new car I'm in.

I decided this was important to me, but our local drifting club couldn't support the idea of funding such a car, so I decided to buy one and do it myself!

Tangerine cost me a whole $400. I had left a note on this car over 5 years ago! Acquired from a lovely music teacher who owned the car for 28 years.

The power steering squealed, the distributor leaked, shocks blown, and the thermostat was stuck open. Otherwise it ran and bumbled around town with the simple clunks you'd expect from an 34 year old Toyota. Remember I said this started only 10 days ago? Yeah, we got cracking.

[caption id="" align="aligncenter" width="1024"] Out came the old, super long knuckles and in popped the new heavily shortened knuckles. These also have reduced ackerman. Reducing ackerman allows the front wheels to be closer to parallel when at full steering lock. This is Super helpful to drifting, as the trailing steering wheel tends to drag due to the differences in angle caused by ackerman. Warren from BCworks supplied the knuckles and helped me create the longer lower control arms.[/caption]

Some of the first basic mods were simple. Longer lower control arms, and shortened steering knuckles. If you want, you can use this post as a minor guide to how to assemble an awesome Corolla for cheap.

By lengthening the LCA's 40mm we gained -4* degrees of camber on the front. It's a really approximate formula, but every 10mm you add you adjust camber but -1* degree. The benefit of this mod, is you get to keep your pleasant and quiet, stock upper strut mounts. Not only does your engine bay look unmodified on inspection, but this mod is a $50 mod, versus the $250 camber plates. Also, you're track width, the distance between both front wheels, increases, which actually reduces body roll. Camber plates might add camber, but they push the strut tower tops inwards, toward each other, this is an expensive way to increase body roll!!!

Why would a beginner car need modified steering knuckles? Some people believe that knuckles are an advanced modification, I disagree. Increasing steering lock is a safety device when learning to drift. You're going to spin out quite a bit when learning to drift. To drift a corner well is a balance of many different factors, you'll mess up a lot at the start. By being able to steer a greater distance to lock, you'll more often rescue spins, and reduce your chance of crashing.

[caption id="" align="aligncenter" width="1024"]

Out came the old, super long knuckles and in popped the new heavily shortened knuckles. These also have reduced ackerman. Reducing ackerman allows the front wheels to be closer to parallel when at full steering lock. This is Super helpful to drifting, as the trailing steering wheel tends to drag due to the differences in angle caused by ackerman. Warren from BCworks supplied the knuckles and helped me create the longer lower control arms.[/caption]

Some of the first basic mods were simple. Longer lower control arms, and shortened steering knuckles. If you want, you can use this post as a minor guide to how to assemble an awesome Corolla for cheap.

By lengthening the LCA's 40mm we gained -4* degrees of camber on the front. It's a really approximate formula, but every 10mm you add you adjust camber but -1* degree. The benefit of this mod, is you get to keep your pleasant and quiet, stock upper strut mounts. Not only does your engine bay look unmodified on inspection, but this mod is a $50 mod, versus the $250 camber plates. Also, you're track width, the distance between both front wheels, increases, which actually reduces body roll. Camber plates might add camber, but they push the strut tower tops inwards, toward each other, this is an expensive way to increase body roll!!!

Why would a beginner car need modified steering knuckles? Some people believe that knuckles are an advanced modification, I disagree. Increasing steering lock is a safety device when learning to drift. You're going to spin out quite a bit when learning to drift. To drift a corner well is a balance of many different factors, you'll mess up a lot at the start. By being able to steer a greater distance to lock, you'll more often rescue spins, and reduce your chance of crashing.

[caption id="" align="aligncenter" width="1024"] Much more steering angle (lock) than stock. Though some ackerman still remains (not pictured). More steering lock is available with a bit of grinding to the lower control arm lip.[/caption]

What's important in a knuckle length adjustment? By reducing the length of the tie rod pickup point, in relation to the ball joint, you increase steering lock. The steering rack can only move so far left and right. By having the tie rod push on a point closer to the ball joint, this limited movement of the steering rack is translated into more turn of the wheel. Thus more steering lock.

These BCworks knuckles also have reduced ackerman. Ackerman is an affect that allows the two front wheels to turn at different angles when going around a corner. While turning, the inner wheel travels on a smaller radius than the other one.

[caption id="" align="aligncenter" width="631"]

Much more steering angle (lock) than stock. Though some ackerman still remains (not pictured). More steering lock is available with a bit of grinding to the lower control arm lip.[/caption]

What's important in a knuckle length adjustment? By reducing the length of the tie rod pickup point, in relation to the ball joint, you increase steering lock. The steering rack can only move so far left and right. By having the tie rod push on a point closer to the ball joint, this limited movement of the steering rack is translated into more turn of the wheel. Thus more steering lock.

These BCworks knuckles also have reduced ackerman. Ackerman is an affect that allows the two front wheels to turn at different angles when going around a corner. While turning, the inner wheel travels on a smaller radius than the other one.

[caption id="" align="aligncenter" width="631"] Most cars have what is shown as "true ackerman". This can cause the trailing wheel during a drift to drag, which promotes weight transfer to the front of the car and spinning out. Removing ackerman will result in more Parallel steering, which allows the car to drift at a faster rate of travel, with less tire wear, and less spinning out![/caption]

Most cars have what is shown as "true ackerman". This can cause the trailing wheel during a drift to drag, which promotes weight transfer to the front of the car and spinning out. Removing ackerman will result in more Parallel steering, which allows the car to drift at a faster rate of travel, with less tire wear, and less spinning out![/caption]

[caption id="" align="aligncenter" width="1024"]

[caption id="" align="aligncenter" width="1024"] Lengthening the Lower control arms (LCA) required lengthening the tie rods to match. These 70-73 Toyota Corona sleeves were 20mm longer. Though not entirely ideal compared to the 40mm we lengthened the control arms, these will do just fine for $23 per side.[/caption]

[caption id="" align="aligncenter" width="1024"]

Lengthening the Lower control arms (LCA) required lengthening the tie rods to match. These 70-73 Toyota Corona sleeves were 20mm longer. Though not entirely ideal compared to the 40mm we lengthened the control arms, these will do just fine for $23 per side.[/caption]

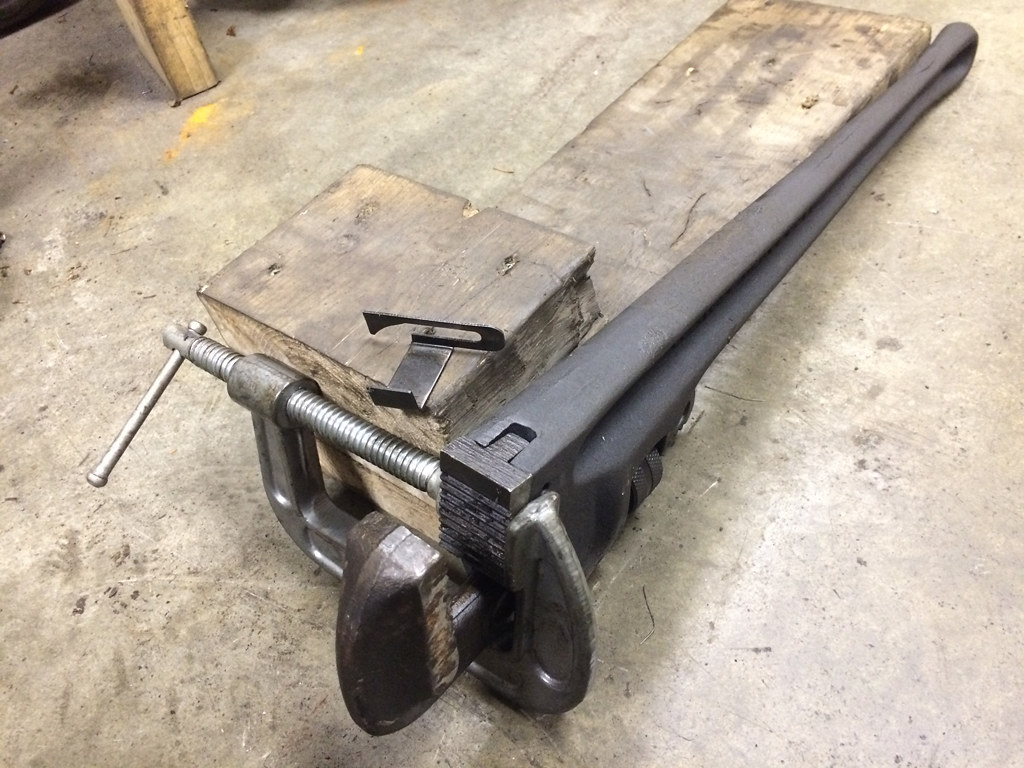

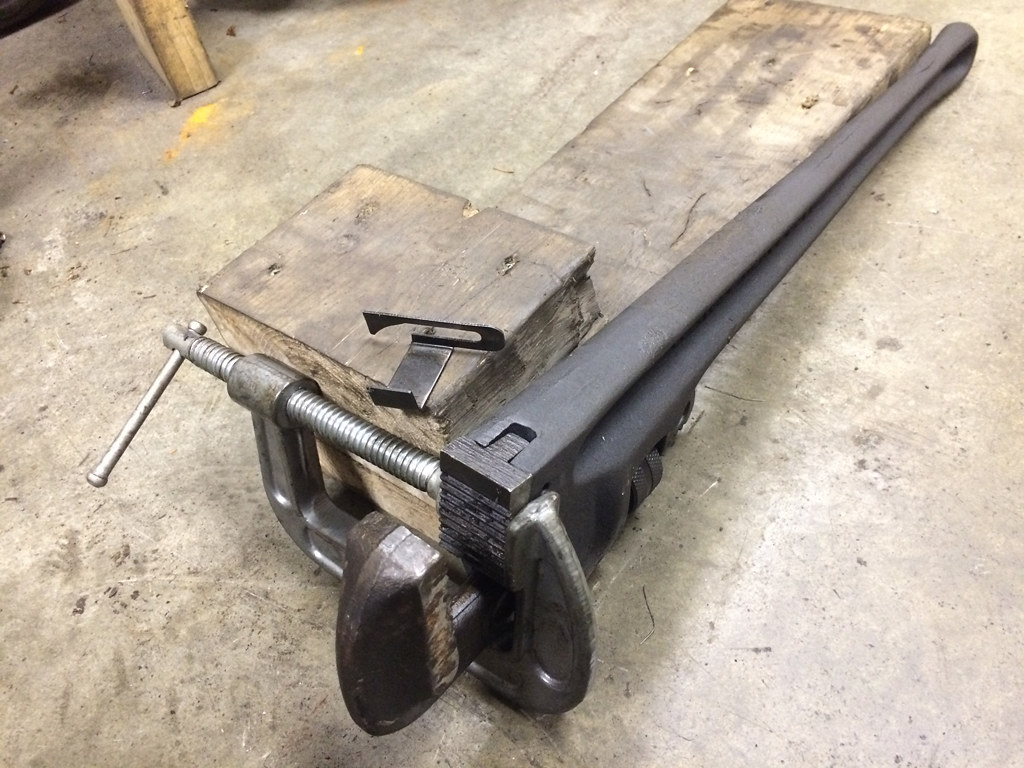

[caption id="" align="aligncenter" width="1024"] Getting the tie rod sleeves to unthread from the inner and outer tie rod ends was a chore without a proper vice, so I made one. A C-clamp and spare pipe wrench resulted in a secure hold while a second pipe wrench reefed it all apart.[/caption]

So you're wondering, 'Automatic Quinn? That won't be helpful!'. I agree, it's not as easy to drift automatic cars, especially under-powered. However, there is a reason to the madness besides reducing build costs. Clutches are the devil when you're trying to get comfortable with the feeling of sliding a car. The first moment a car begins to slide is often a panic moment with most drivers, this is almost entirely a stall moment, where the student clams up and prepares for a collision or explosion that's not going to occur. lol Automatic keeps things chill in that sense. Removing the clutch removes some of the complexity of ones first slides; telling a person press the clutch and the gas, drop the clutch, and then turn into a corner all at the same time, is a bit heavy of an initial experience.

Ultimately the goal of this car is not to be an amazing all around drift car, but rather to introduce the very basics, hand brake 90*s, hand brake 180*s, Donuts, and some small 1st/2nd gear slides. My KA swapped AE71 will be a much better car for those intermediate students.

Getting the tie rod sleeves to unthread from the inner and outer tie rod ends was a chore without a proper vice, so I made one. A C-clamp and spare pipe wrench resulted in a secure hold while a second pipe wrench reefed it all apart.[/caption]

So you're wondering, 'Automatic Quinn? That won't be helpful!'. I agree, it's not as easy to drift automatic cars, especially under-powered. However, there is a reason to the madness besides reducing build costs. Clutches are the devil when you're trying to get comfortable with the feeling of sliding a car. The first moment a car begins to slide is often a panic moment with most drivers, this is almost entirely a stall moment, where the student clams up and prepares for a collision or explosion that's not going to occur. lol Automatic keeps things chill in that sense. Removing the clutch removes some of the complexity of ones first slides; telling a person press the clutch and the gas, drop the clutch, and then turn into a corner all at the same time, is a bit heavy of an initial experience.

Ultimately the goal of this car is not to be an amazing all around drift car, but rather to introduce the very basics, hand brake 90*s, hand brake 180*s, Donuts, and some small 1st/2nd gear slides. My KA swapped AE71 will be a much better car for those intermediate students.

[caption id="" align="aligncenter" width="1024"]

[caption id="" align="aligncenter" width="1024"] Some basics for a healthy car, and a lovely diff.[/caption]

Basic maintenance is key. Getting the car running well is paramount to learning. Struggling with a car that barely runs is a regressive learning experience and a waste of time and money! You'll learn almost nothing on a track day with a car that can't idle every time you spin or constantly overheats! One quick old Corolla mod I did was unplug the electric fan control switch. Canadian E7's came with electric fans, I think american ones had mechanical. The electric fan trigger switches always fail in E7's resulting in a fan that never turns on, with it unplugged the fan runs always. It's the safer choice. I noticed when I got the car that the heat came on really slowly. The defogger also just sucked. The two in combination resulted in some frustrating late night test drives. After some investigation I found the arm for the blend door had broken, leaving the air directed out the occupant vents rather than the windshield. A temporary fix was to move the blend door semi-permanently into the defogger position. The thermostat was another animal.

[caption id="" align="aligncenter" width="961"]

Some basics for a healthy car, and a lovely diff.[/caption]

Basic maintenance is key. Getting the car running well is paramount to learning. Struggling with a car that barely runs is a regressive learning experience and a waste of time and money! You'll learn almost nothing on a track day with a car that can't idle every time you spin or constantly overheats! One quick old Corolla mod I did was unplug the electric fan control switch. Canadian E7's came with electric fans, I think american ones had mechanical. The electric fan trigger switches always fail in E7's resulting in a fan that never turns on, with it unplugged the fan runs always. It's the safer choice. I noticed when I got the car that the heat came on really slowly. The defogger also just sucked. The two in combination resulted in some frustrating late night test drives. After some investigation I found the arm for the blend door had broken, leaving the air directed out the occupant vents rather than the windshield. A temporary fix was to move the blend door semi-permanently into the defogger position. The thermostat was another animal.

[caption id="" align="aligncenter" width="961"] I'd never seen this before. This thermostat used a rubber seal for the plunger, which had failed, causing the plunger to remain open. I'm glad it never made it to the water pump or into the rest of the system. Poor design choices, feels very German. I installed a slightly lower temp thermostat for long runs at the track.[/caption]

Cooling is pretty important to drifting, but it doesn't need to be expensive. I installed a new lower temperature thermostat. What that does is allow the thermostat to open a little sooner and keep the idle temperature of the motor just a little bit lower between runs at the track. This allows me to bag on the car for longer of periods of time with reduced downtime between runs. A cheap $10 mod. The next thing I installed was a higher pressure radiator cap, rather than the 13psi stock one, a 16psi cap was put in it's place. Increasing the cap pressure makes boiling harder for the coolant to do. The greater the pressure contained in the system, the higher the temperature the water will boil at. Boiling is unwanted as it introduces air into the cooling system which doesn't cool nearly as well as the water. You can get caps up to 35psi, but I don't feel like having my coolant hoses explode every 6 laps, or have 35psi of coolant pressure trying to overcome the 34 year old head gasket. Improvements with moderate considerations. The coolant was replaced with water as per track rules, plus it cools better, though doesn't lubricate the water pump as well. I also through in a gauge, as the factory gauges are extremely inaccurate or failed completely.

[caption id="" align="aligncenter" width="1024"]

I'd never seen this before. This thermostat used a rubber seal for the plunger, which had failed, causing the plunger to remain open. I'm glad it never made it to the water pump or into the rest of the system. Poor design choices, feels very German. I installed a slightly lower temp thermostat for long runs at the track.[/caption]

Cooling is pretty important to drifting, but it doesn't need to be expensive. I installed a new lower temperature thermostat. What that does is allow the thermostat to open a little sooner and keep the idle temperature of the motor just a little bit lower between runs at the track. This allows me to bag on the car for longer of periods of time with reduced downtime between runs. A cheap $10 mod. The next thing I installed was a higher pressure radiator cap, rather than the 13psi stock one, a 16psi cap was put in it's place. Increasing the cap pressure makes boiling harder for the coolant to do. The greater the pressure contained in the system, the higher the temperature the water will boil at. Boiling is unwanted as it introduces air into the cooling system which doesn't cool nearly as well as the water. You can get caps up to 35psi, but I don't feel like having my coolant hoses explode every 6 laps, or have 35psi of coolant pressure trying to overcome the 34 year old head gasket. Improvements with moderate considerations. The coolant was replaced with water as per track rules, plus it cools better, though doesn't lubricate the water pump as well. I also through in a gauge, as the factory gauges are extremely inaccurate or failed completely.

[caption id="" align="aligncenter" width="1024"] Never trust your stock temperature gauge!!! Ever! They almost always lie. Keep that car chilling at 190* F (90*C) as that's a dope temp. 210* and some cars start to have miss fires.[/caption]

[caption id="" align="aligncenter" width="576"]

Never trust your stock temperature gauge!!! Ever! They almost always lie. Keep that car chilling at 190* F (90*C) as that's a dope temp. 210* and some cars start to have miss fires.[/caption]

[caption id="" align="aligncenter" width="576"] I tossed a wheel into it as well as it was sitting around and the stock wheel looked to have been chewed by a dog.[/caption]

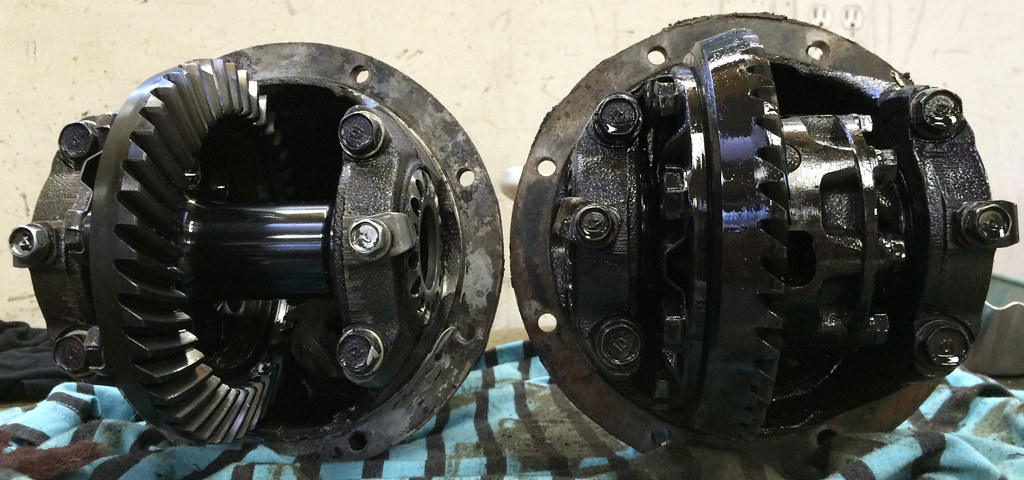

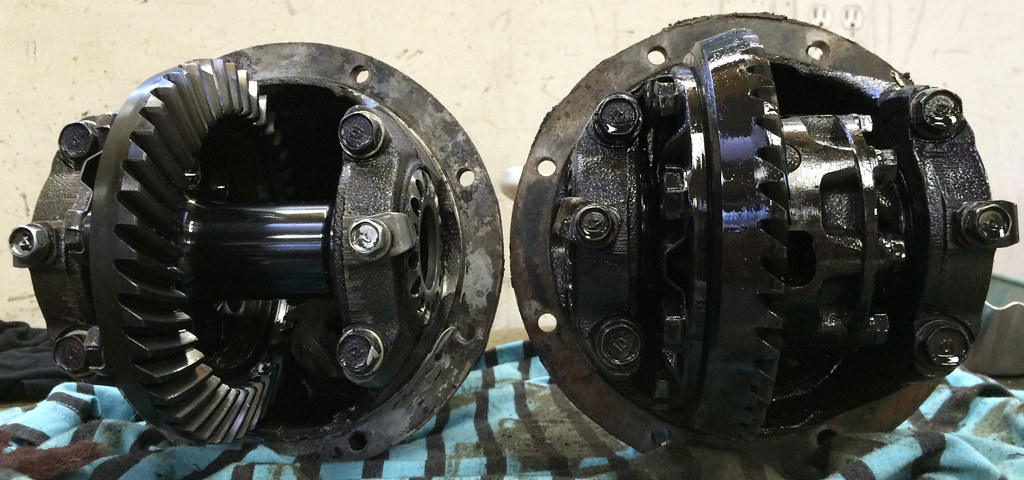

Next up was the differential. This is a crucial part of a good working drift car. If you're going to a drift day with an open differential or a worn out LSD, you're going to have a bad time. The entire control during a drift, is the speed of the rear wheels and the direction of your steering. These are the primary factors directing the vehicle during a slide. Since we solved the steering angle limitations, it was now time to improve the differential for sliding. Out popped the old, open diff, and the new Locked diff popped in.

What's an open, versus a locked diff? A differential is a mechanical device that divides the power from the engine, delivered by the drive shaft, equally to both rear wheels. The engine only provides one driveshaft, so the differential is there to divide this power so both rear wheels can be powered. There are different types that accomplish this goal different ways. An open differential is found in 99% of all vehicles, it's the cheapest, most reliable and most comfortable design balancing all those factors as best as it can.

I'm not going to reinvent the wheel here. Just watch a video. lol

[embed]https://www.youtube.com/watch?v=gIGvhvOhLHU[/embed]

This video is great. Why's an open differential shitty for drifting? Your ability to control push, and angle during a drift is controlled by the gas pedal. If the rear wheels receive uneven loads/grip of the road, the wheel with the least grip or load will spin much faster than the other. This happens quickly, and unpredictably, which makes controlling the slide very complicated and difficult. Sometimes this can result in a sudden and unexpected spin or even crash!

Limited Slip Differentials are the next most common type of differential found in cars, sometimes called a Posi-trac, or shortened to LSD. These are much better for drifting than an open diff as the wheel speed, and your control of it is much more predictable. However, most older LSD's are worn out and basically operate the same as an open differential. They are costly to rebuild or replace in most cases. Drifting is very hard on LSD's and often wears them out quickly.

I prefer completely Locked differentials, which for daily driving sucks ass, but for drifting is extremely reliable and predictable. Welding open and sometimes LSD differentials is common. Making them into locked differentials. Welded diff's are a hot topic at the track, but it is a tricky type of welding, as the metal is often contaminated by the differential gear oil the diff rests in. It is also difficult to weld, as differentials are usually made using cast steel. Cast requires a lot of heat to penetrate your weld deeply enough to be a long lasting weld.

Another alternative to converting your differential into a locked differential is buying one. Many vehicles have Mini-spools which replace the small spider gears of the open differential, or Full-spools which replace the whole cast unit entirely. These are the most reliable choice of any of the differential options, and luckily enough the second cheapest, only to welding your original diff. LSD's are often $1500+, welded diffs often explode causing a lot of damage, but spools can sometimes be a cheap as $30! I acquired a while back a full spool for my Corolla. People in the Corolla community ignore these and often don't even know they exist for their cars. The mini-spools for E7's are only $40 and work well. The full spools are $150 and will last you a life time.

You can find them easily on here for your Corolla.

Speedway motors $40 8-bolt Toyota mini spool (6.3" S-code diff & early 6.7" T-code)

Speedway motors $150 8-bolt Toyota Full Spool (6.3" S-code & early 6.7" T-code)

Speedway motors $150 10-bolt Toyota Full Spool (Late 6.7" T-code only)

(Note: Early 6.7" -zenki- rear axles used the same spline as the S-code diffs, later 6.7" -kouki- used a larger spline.)

[caption id="" align="aligncenter" width="1024"]

I tossed a wheel into it as well as it was sitting around and the stock wheel looked to have been chewed by a dog.[/caption]

Next up was the differential. This is a crucial part of a good working drift car. If you're going to a drift day with an open differential or a worn out LSD, you're going to have a bad time. The entire control during a drift, is the speed of the rear wheels and the direction of your steering. These are the primary factors directing the vehicle during a slide. Since we solved the steering angle limitations, it was now time to improve the differential for sliding. Out popped the old, open diff, and the new Locked diff popped in.

What's an open, versus a locked diff? A differential is a mechanical device that divides the power from the engine, delivered by the drive shaft, equally to both rear wheels. The engine only provides one driveshaft, so the differential is there to divide this power so both rear wheels can be powered. There are different types that accomplish this goal different ways. An open differential is found in 99% of all vehicles, it's the cheapest, most reliable and most comfortable design balancing all those factors as best as it can.

I'm not going to reinvent the wheel here. Just watch a video. lol

[embed]https://www.youtube.com/watch?v=gIGvhvOhLHU[/embed]

This video is great. Why's an open differential shitty for drifting? Your ability to control push, and angle during a drift is controlled by the gas pedal. If the rear wheels receive uneven loads/grip of the road, the wheel with the least grip or load will spin much faster than the other. This happens quickly, and unpredictably, which makes controlling the slide very complicated and difficult. Sometimes this can result in a sudden and unexpected spin or even crash!

Limited Slip Differentials are the next most common type of differential found in cars, sometimes called a Posi-trac, or shortened to LSD. These are much better for drifting than an open diff as the wheel speed, and your control of it is much more predictable. However, most older LSD's are worn out and basically operate the same as an open differential. They are costly to rebuild or replace in most cases. Drifting is very hard on LSD's and often wears them out quickly.

I prefer completely Locked differentials, which for daily driving sucks ass, but for drifting is extremely reliable and predictable. Welding open and sometimes LSD differentials is common. Making them into locked differentials. Welded diff's are a hot topic at the track, but it is a tricky type of welding, as the metal is often contaminated by the differential gear oil the diff rests in. It is also difficult to weld, as differentials are usually made using cast steel. Cast requires a lot of heat to penetrate your weld deeply enough to be a long lasting weld.

Another alternative to converting your differential into a locked differential is buying one. Many vehicles have Mini-spools which replace the small spider gears of the open differential, or Full-spools which replace the whole cast unit entirely. These are the most reliable choice of any of the differential options, and luckily enough the second cheapest, only to welding your original diff. LSD's are often $1500+, welded diffs often explode causing a lot of damage, but spools can sometimes be a cheap as $30! I acquired a while back a full spool for my Corolla. People in the Corolla community ignore these and often don't even know they exist for their cars. The mini-spools for E7's are only $40 and work well. The full spools are $150 and will last you a life time.

You can find them easily on here for your Corolla.

Speedway motors $40 8-bolt Toyota mini spool (6.3" S-code diff & early 6.7" T-code)

Speedway motors $150 8-bolt Toyota Full Spool (6.3" S-code & early 6.7" T-code)

Speedway motors $150 10-bolt Toyota Full Spool (Late 6.7" T-code only)

(Note: Early 6.7" -zenki- rear axles used the same spline as the S-code diffs, later 6.7" -kouki- used a larger spline.)

[caption id="" align="aligncenter" width="1024"] Full spool on the left, stock open diff on the right. The full spool is much less effort for the engine to spin!!![/caption]

After a few test runs the motor started choking and dying. My plan is to leave the motor and transmission as close to stock as possible. I generally hate the idea of increasing an engines power. The sacrifice is money and reliability always. In order to keep the car going to as many events as possible, it was important to make it run well, but also remain reliable. When it started running poorly I hobbled it over to Joel's house, who is the other half of BCworks. He's a whiz with getting old shitty things running well. Immediately he concluded there was junk in the jets. After carb tear down, and reassembly it was back running stronger than ever! The gas tank hadn't sloshed that hard ever in it's life, so a bunch of old grit had unsettled made it's way past my fuel filter and clogged the jets. I replaced the fuel filter for safe measure. While we were at it, we checked the compression of all the cylinders which was near 160psi across all of them, a healthy little fellow!! Lastly I increased the tension slightly on the transmission kick down cable. In older cars there is a cable that is attached to the throttle, if you tromp the throttle down a certain amount, it will tug the transmission kick down cable. This cable causes the automatic transmission to shift down into a more acceleration oriented gear. By tightening this up a bit, it encourages the engine to wait a little longer before shifting up to longer, top speed gears. This new tension also promotes dropping down into more acceleration oriented gears sooner, which means the transmission is less likely to "shift hunt" during drifts. Drifting can often confuse automatic transmissions as you are constantly changing grip and load on the the tires, as well as your throttle position. The transmission is often confused and jumps back and forth between gears unpredictably. When controlling wheel speed with your throttle these sudden gear changes can massively affect wheel speed and ultimately your control of grip at that moment. Keeping the transmission in one gear improves the predictableness of your throttle control. This is real benefit of a manual transmission, not as much the clutch itself, though helpful.

Some new plugs, fresh oil, and we've caught up to where I'm at with the car right now. In the last 10 days I've put in about 36 hours of work, and I'm ready for a bit of a break from the car for a day or two. However there are still things to touch up before the track day on the 27th. I need a new Distributor O-ring and have a bunch of new suspension to install. I also have to decide if I hate the stickers I fucked up installing on the doors too. I might just leave them, but I wrecked them, and they feel pretty aggressive. However, I already got stopped in the street by a passing motorist to inquire about the car, so they might be more helpful than ugly. lol

[caption id="" align="aligncenter" width="1024"]

Full spool on the left, stock open diff on the right. The full spool is much less effort for the engine to spin!!![/caption]

After a few test runs the motor started choking and dying. My plan is to leave the motor and transmission as close to stock as possible. I generally hate the idea of increasing an engines power. The sacrifice is money and reliability always. In order to keep the car going to as many events as possible, it was important to make it run well, but also remain reliable. When it started running poorly I hobbled it over to Joel's house, who is the other half of BCworks. He's a whiz with getting old shitty things running well. Immediately he concluded there was junk in the jets. After carb tear down, and reassembly it was back running stronger than ever! The gas tank hadn't sloshed that hard ever in it's life, so a bunch of old grit had unsettled made it's way past my fuel filter and clogged the jets. I replaced the fuel filter for safe measure. While we were at it, we checked the compression of all the cylinders which was near 160psi across all of them, a healthy little fellow!! Lastly I increased the tension slightly on the transmission kick down cable. In older cars there is a cable that is attached to the throttle, if you tromp the throttle down a certain amount, it will tug the transmission kick down cable. This cable causes the automatic transmission to shift down into a more acceleration oriented gear. By tightening this up a bit, it encourages the engine to wait a little longer before shifting up to longer, top speed gears. This new tension also promotes dropping down into more acceleration oriented gears sooner, which means the transmission is less likely to "shift hunt" during drifts. Drifting can often confuse automatic transmissions as you are constantly changing grip and load on the the tires, as well as your throttle position. The transmission is often confused and jumps back and forth between gears unpredictably. When controlling wheel speed with your throttle these sudden gear changes can massively affect wheel speed and ultimately your control of grip at that moment. Keeping the transmission in one gear improves the predictableness of your throttle control. This is real benefit of a manual transmission, not as much the clutch itself, though helpful.

Some new plugs, fresh oil, and we've caught up to where I'm at with the car right now. In the last 10 days I've put in about 36 hours of work, and I'm ready for a bit of a break from the car for a day or two. However there are still things to touch up before the track day on the 27th. I need a new Distributor O-ring and have a bunch of new suspension to install. I also have to decide if I hate the stickers I fucked up installing on the doors too. I might just leave them, but I wrecked them, and they feel pretty aggressive. However, I already got stopped in the street by a passing motorist to inquire about the car, so they might be more helpful than ugly. lol

[caption id="" align="aligncenter" width="1024"] Managed to score a Snell approved open face, almost new for $80! I'm stoked.[/caption]

[caption id="" align="aligncenter" width="711"]

Managed to score a Snell approved open face, almost new for $80! I'm stoked.[/caption]

[caption id="" align="aligncenter" width="711"] I picked up these front coils, not pictured is the KYB shock and TRD spring combo I also acquired for the rear. Sadly the hubs are slightly bent on these, and they're AE86 brake bolt pattern, so I'll be chopping the strut tubes in the middle and welding them onto the proper E7 hubs. Won't be done for the practice day.[/caption]

So let's figure this out, roughly speaking, my bank account has seen a loss of about $1200 to build this car so far. It's not quite done yet, but it's closer than it was before I started. This car will probably drift okay. It won't be the worlds best, it's probably kinda suck, but that's why other people will be allowed to use it. There's still more work to go. Below is a rough cost structure of the things that went into the car, minus fluids, insurance and government costs, mid night snacks, and other things. I'm fucking broke now. It took me 2 years to save up that much dough, but hopefully others learning will feel really rewarding for me.

Purchase Price $400

Transmission cooler fittings $25.88

Tie rod sleeves, 38.06

Fuel filter 9.08

Oil filter 12.44

Plugs 11.52

Fuel Pump 30.28

Transmission cooler lines $8.19

Clamps 4.08

Suspension $120

Knuckles and LCA's $50

Tuning $3.09

Stickers $20

Helmet $80

Gauge $10

$822.62 Approximately.

Don't forget the thank yous!

Purchase of the car (Thanks to Gwendolyn!)

Rear Speedway motors full spool (Thanks Colby & Brian!)

Full suspension, front T3 coilover with 7kg springs, KYB shocks front and rear, with mystery rear TRD springs (Thanks Jason!)

BC works shortened and reduced ackerman knuckles, and lengthened LCA's (Thanks Warren!)

Mechanical Temp Gauge (Thanks Nick!)

Transmission oil cooler (Thanks Potato Dave!)

Grant Steering wheel and hub (Thanks Corey!)

Set of 4 dope 13"s (Thanks Eric!)

Temperature gauge sender (Thanks Nick and Haley!)

Suspension acquisition (Thanks Brett and Andrew!)

Garage space, few tools (Thanks Dugan!)

Engine troubleshooting (Thanks Joel!)

Last Minute stickers (Thanks Trevor!)

Fuck, I'm sure there are others. I've just been typing for 2 hours and brain dead.

Right, current pics. Good way to end this installment of the ghetto school car.

I picked up these front coils, not pictured is the KYB shock and TRD spring combo I also acquired for the rear. Sadly the hubs are slightly bent on these, and they're AE86 brake bolt pattern, so I'll be chopping the strut tubes in the middle and welding them onto the proper E7 hubs. Won't be done for the practice day.[/caption]

So let's figure this out, roughly speaking, my bank account has seen a loss of about $1200 to build this car so far. It's not quite done yet, but it's closer than it was before I started. This car will probably drift okay. It won't be the worlds best, it's probably kinda suck, but that's why other people will be allowed to use it. There's still more work to go. Below is a rough cost structure of the things that went into the car, minus fluids, insurance and government costs, mid night snacks, and other things. I'm fucking broke now. It took me 2 years to save up that much dough, but hopefully others learning will feel really rewarding for me.

Purchase Price $400

Transmission cooler fittings $25.88

Tie rod sleeves, 38.06

Fuel filter 9.08

Oil filter 12.44

Plugs 11.52

Fuel Pump 30.28

Transmission cooler lines $8.19

Clamps 4.08

Suspension $120

Knuckles and LCA's $50

Tuning $3.09

Stickers $20

Helmet $80

Gauge $10

$822.62 Approximately.

Don't forget the thank yous!

Purchase of the car (Thanks to Gwendolyn!)

Rear Speedway motors full spool (Thanks Colby & Brian!)

Full suspension, front T3 coilover with 7kg springs, KYB shocks front and rear, with mystery rear TRD springs (Thanks Jason!)

BC works shortened and reduced ackerman knuckles, and lengthened LCA's (Thanks Warren!)

Mechanical Temp Gauge (Thanks Nick!)

Transmission oil cooler (Thanks Potato Dave!)

Grant Steering wheel and hub (Thanks Corey!)

Set of 4 dope 13"s (Thanks Eric!)

Temperature gauge sender (Thanks Nick and Haley!)

Suspension acquisition (Thanks Brett and Andrew!)

Garage space, few tools (Thanks Dugan!)

Engine troubleshooting (Thanks Joel!)

Last Minute stickers (Thanks Trevor!)

Fuck, I'm sure there are others. I've just been typing for 2 hours and brain dead.

Right, current pics. Good way to end this installment of the ghetto school car.

Share this post

Back to SPEED HERO Blog

This purchase was justified in my brain by the added duty beyond a daily driver, of being a tool of education, a racing school student car. I'd been giving formal and information racing instruction during our drifting events for years now. For some it was successful for others, not so much. I realized recently what a major differentiating factor was: the cars!

Some students showed up in good working cars, that ran well, and were logically or accidentally setup to drift well. However for a majority of people learning to drift, and supplying their own drift cars, budgets were tight, experience was nearly nil, and they were also on the path of learning to work on cars at the same time of learning to operate them at accelerated rates. These two paths of learning are commonly combined but far from complimentary, let alone affordable! Much of my time giving instruction was spent on tire pressures, tire choices, yelling at people who tell me they don't need a parking brake, and trying to get cars just to idle. "Bro, the clutch only slips a bit!" is not something supportive of a reliable learning experience.

I will continue to believe that drifting is easy, like super easy. What's difficult is getting the opportunity to make safe mistakes in a well setup car in a safe location. These factors change what would be 4 hours to perfect into 2-3 years. lol Seriously speaking, by providing a reliable and consistent experience for students, even if it's only for a few laps, the skills will fruit much quicker. For me instructing, I'm hoping their driving habits and flaws will be much more obvious with a consistent vehicle than trying to diagnosis mid corner if they suck or it's the random new car I'm in.

I decided this was important to me, but our local drifting club couldn't support the idea of funding such a car, so I decided to buy one and do it myself!

Tangerine cost me a whole $400. I had left a note on this car over 5 years ago! Acquired from a lovely music teacher who owned the car for 28 years.

The power steering squealed, the distributor leaked, shocks blown, and the thermostat was stuck open. Otherwise it ran and bumbled around town with the simple clunks you'd expect from an 34 year old Toyota. Remember I said this started only 10 days ago? Yeah, we got cracking.

[caption id="" align="aligncenter" width="1024"]

This purchase was justified in my brain by the added duty beyond a daily driver, of being a tool of education, a racing school student car. I'd been giving formal and information racing instruction during our drifting events for years now. For some it was successful for others, not so much. I realized recently what a major differentiating factor was: the cars!

Some students showed up in good working cars, that ran well, and were logically or accidentally setup to drift well. However for a majority of people learning to drift, and supplying their own drift cars, budgets were tight, experience was nearly nil, and they were also on the path of learning to work on cars at the same time of learning to operate them at accelerated rates. These two paths of learning are commonly combined but far from complimentary, let alone affordable! Much of my time giving instruction was spent on tire pressures, tire choices, yelling at people who tell me they don't need a parking brake, and trying to get cars just to idle. "Bro, the clutch only slips a bit!" is not something supportive of a reliable learning experience.

I will continue to believe that drifting is easy, like super easy. What's difficult is getting the opportunity to make safe mistakes in a well setup car in a safe location. These factors change what would be 4 hours to perfect into 2-3 years. lol Seriously speaking, by providing a reliable and consistent experience for students, even if it's only for a few laps, the skills will fruit much quicker. For me instructing, I'm hoping their driving habits and flaws will be much more obvious with a consistent vehicle than trying to diagnosis mid corner if they suck or it's the random new car I'm in.

I decided this was important to me, but our local drifting club couldn't support the idea of funding such a car, so I decided to buy one and do it myself!

Tangerine cost me a whole $400. I had left a note on this car over 5 years ago! Acquired from a lovely music teacher who owned the car for 28 years.

The power steering squealed, the distributor leaked, shocks blown, and the thermostat was stuck open. Otherwise it ran and bumbled around town with the simple clunks you'd expect from an 34 year old Toyota. Remember I said this started only 10 days ago? Yeah, we got cracking.

[caption id="" align="aligncenter" width="1024"] Out came the old, super long knuckles and in popped the new heavily shortened knuckles. These also have reduced ackerman. Reducing ackerman allows the front wheels to be closer to parallel when at full steering lock. This is Super helpful to drifting, as the trailing steering wheel tends to drag due to the differences in angle caused by ackerman. Warren from BCworks supplied the knuckles and helped me create the longer lower control arms.[/caption]

Some of the first basic mods were simple. Longer lower control arms, and shortened steering knuckles. If you want, you can use this post as a minor guide to how to assemble an awesome Corolla for cheap.

By lengthening the LCA's 40mm we gained -4* degrees of camber on the front. It's a really approximate formula, but every 10mm you add you adjust camber but -1* degree. The benefit of this mod, is you get to keep your pleasant and quiet, stock upper strut mounts. Not only does your engine bay look unmodified on inspection, but this mod is a $50 mod, versus the $250 camber plates. Also, you're track width, the distance between both front wheels, increases, which actually reduces body roll. Camber plates might add camber, but they push the strut tower tops inwards, toward each other, this is an expensive way to increase body roll!!!

Why would a beginner car need modified steering knuckles? Some people believe that knuckles are an advanced modification, I disagree. Increasing steering lock is a safety device when learning to drift. You're going to spin out quite a bit when learning to drift. To drift a corner well is a balance of many different factors, you'll mess up a lot at the start. By being able to steer a greater distance to lock, you'll more often rescue spins, and reduce your chance of crashing.

[caption id="" align="aligncenter" width="1024"]

Out came the old, super long knuckles and in popped the new heavily shortened knuckles. These also have reduced ackerman. Reducing ackerman allows the front wheels to be closer to parallel when at full steering lock. This is Super helpful to drifting, as the trailing steering wheel tends to drag due to the differences in angle caused by ackerman. Warren from BCworks supplied the knuckles and helped me create the longer lower control arms.[/caption]

Some of the first basic mods were simple. Longer lower control arms, and shortened steering knuckles. If you want, you can use this post as a minor guide to how to assemble an awesome Corolla for cheap.

By lengthening the LCA's 40mm we gained -4* degrees of camber on the front. It's a really approximate formula, but every 10mm you add you adjust camber but -1* degree. The benefit of this mod, is you get to keep your pleasant and quiet, stock upper strut mounts. Not only does your engine bay look unmodified on inspection, but this mod is a $50 mod, versus the $250 camber plates. Also, you're track width, the distance between both front wheels, increases, which actually reduces body roll. Camber plates might add camber, but they push the strut tower tops inwards, toward each other, this is an expensive way to increase body roll!!!

Why would a beginner car need modified steering knuckles? Some people believe that knuckles are an advanced modification, I disagree. Increasing steering lock is a safety device when learning to drift. You're going to spin out quite a bit when learning to drift. To drift a corner well is a balance of many different factors, you'll mess up a lot at the start. By being able to steer a greater distance to lock, you'll more often rescue spins, and reduce your chance of crashing.

[caption id="" align="aligncenter" width="1024"] Much more steering angle (lock) than stock. Though some ackerman still remains (not pictured). More steering lock is available with a bit of grinding to the lower control arm lip.[/caption]

What's important in a knuckle length adjustment? By reducing the length of the tie rod pickup point, in relation to the ball joint, you increase steering lock. The steering rack can only move so far left and right. By having the tie rod push on a point closer to the ball joint, this limited movement of the steering rack is translated into more turn of the wheel. Thus more steering lock.

These BCworks knuckles also have reduced ackerman. Ackerman is an affect that allows the two front wheels to turn at different angles when going around a corner. While turning, the inner wheel travels on a smaller radius than the other one.

[caption id="" align="aligncenter" width="631"]

Much more steering angle (lock) than stock. Though some ackerman still remains (not pictured). More steering lock is available with a bit of grinding to the lower control arm lip.[/caption]

What's important in a knuckle length adjustment? By reducing the length of the tie rod pickup point, in relation to the ball joint, you increase steering lock. The steering rack can only move so far left and right. By having the tie rod push on a point closer to the ball joint, this limited movement of the steering rack is translated into more turn of the wheel. Thus more steering lock.

These BCworks knuckles also have reduced ackerman. Ackerman is an affect that allows the two front wheels to turn at different angles when going around a corner. While turning, the inner wheel travels on a smaller radius than the other one.

[caption id="" align="aligncenter" width="631"] Most cars have what is shown as "true ackerman". This can cause the trailing wheel during a drift to drag, which promotes weight transfer to the front of the car and spinning out. Removing ackerman will result in more Parallel steering, which allows the car to drift at a faster rate of travel, with less tire wear, and less spinning out![/caption]

Most cars have what is shown as "true ackerman". This can cause the trailing wheel during a drift to drag, which promotes weight transfer to the front of the car and spinning out. Removing ackerman will result in more Parallel steering, which allows the car to drift at a faster rate of travel, with less tire wear, and less spinning out![/caption]

[caption id="" align="aligncenter" width="1024"]

[caption id="" align="aligncenter" width="1024"] Lengthening the Lower control arms (LCA) required lengthening the tie rods to match. These 70-73 Toyota Corona sleeves were 20mm longer. Though not entirely ideal compared to the 40mm we lengthened the control arms, these will do just fine for $23 per side.[/caption]

[caption id="" align="aligncenter" width="1024"]

Lengthening the Lower control arms (LCA) required lengthening the tie rods to match. These 70-73 Toyota Corona sleeves were 20mm longer. Though not entirely ideal compared to the 40mm we lengthened the control arms, these will do just fine for $23 per side.[/caption]

[caption id="" align="aligncenter" width="1024"] Getting the tie rod sleeves to unthread from the inner and outer tie rod ends was a chore without a proper vice, so I made one. A C-clamp and spare pipe wrench resulted in a secure hold while a second pipe wrench reefed it all apart.[/caption]

So you're wondering, 'Automatic Quinn? That won't be helpful!'. I agree, it's not as easy to drift automatic cars, especially under-powered. However, there is a reason to the madness besides reducing build costs. Clutches are the devil when you're trying to get comfortable with the feeling of sliding a car. The first moment a car begins to slide is often a panic moment with most drivers, this is almost entirely a stall moment, where the student clams up and prepares for a collision or explosion that's not going to occur. lol Automatic keeps things chill in that sense. Removing the clutch removes some of the complexity of ones first slides; telling a person press the clutch and the gas, drop the clutch, and then turn into a corner all at the same time, is a bit heavy of an initial experience.

Ultimately the goal of this car is not to be an amazing all around drift car, but rather to introduce the very basics, hand brake 90*s, hand brake 180*s, Donuts, and some small 1st/2nd gear slides. My KA swapped AE71 will be a much better car for those intermediate students.

Getting the tie rod sleeves to unthread from the inner and outer tie rod ends was a chore without a proper vice, so I made one. A C-clamp and spare pipe wrench resulted in a secure hold while a second pipe wrench reefed it all apart.[/caption]

So you're wondering, 'Automatic Quinn? That won't be helpful!'. I agree, it's not as easy to drift automatic cars, especially under-powered. However, there is a reason to the madness besides reducing build costs. Clutches are the devil when you're trying to get comfortable with the feeling of sliding a car. The first moment a car begins to slide is often a panic moment with most drivers, this is almost entirely a stall moment, where the student clams up and prepares for a collision or explosion that's not going to occur. lol Automatic keeps things chill in that sense. Removing the clutch removes some of the complexity of ones first slides; telling a person press the clutch and the gas, drop the clutch, and then turn into a corner all at the same time, is a bit heavy of an initial experience.

Ultimately the goal of this car is not to be an amazing all around drift car, but rather to introduce the very basics, hand brake 90*s, hand brake 180*s, Donuts, and some small 1st/2nd gear slides. My KA swapped AE71 will be a much better car for those intermediate students.

[caption id="" align="aligncenter" width="1024"]

[caption id="" align="aligncenter" width="1024"] Some basics for a healthy car, and a lovely diff.[/caption]

Basic maintenance is key. Getting the car running well is paramount to learning. Struggling with a car that barely runs is a regressive learning experience and a waste of time and money! You'll learn almost nothing on a track day with a car that can't idle every time you spin or constantly overheats! One quick old Corolla mod I did was unplug the electric fan control switch. Canadian E7's came with electric fans, I think american ones had mechanical. The electric fan trigger switches always fail in E7's resulting in a fan that never turns on, with it unplugged the fan runs always. It's the safer choice. I noticed when I got the car that the heat came on really slowly. The defogger also just sucked. The two in combination resulted in some frustrating late night test drives. After some investigation I found the arm for the blend door had broken, leaving the air directed out the occupant vents rather than the windshield. A temporary fix was to move the blend door semi-permanently into the defogger position. The thermostat was another animal.

[caption id="" align="aligncenter" width="961"]

Some basics for a healthy car, and a lovely diff.[/caption]

Basic maintenance is key. Getting the car running well is paramount to learning. Struggling with a car that barely runs is a regressive learning experience and a waste of time and money! You'll learn almost nothing on a track day with a car that can't idle every time you spin or constantly overheats! One quick old Corolla mod I did was unplug the electric fan control switch. Canadian E7's came with electric fans, I think american ones had mechanical. The electric fan trigger switches always fail in E7's resulting in a fan that never turns on, with it unplugged the fan runs always. It's the safer choice. I noticed when I got the car that the heat came on really slowly. The defogger also just sucked. The two in combination resulted in some frustrating late night test drives. After some investigation I found the arm for the blend door had broken, leaving the air directed out the occupant vents rather than the windshield. A temporary fix was to move the blend door semi-permanently into the defogger position. The thermostat was another animal.

[caption id="" align="aligncenter" width="961"] I'd never seen this before. This thermostat used a rubber seal for the plunger, which had failed, causing the plunger to remain open. I'm glad it never made it to the water pump or into the rest of the system. Poor design choices, feels very German. I installed a slightly lower temp thermostat for long runs at the track.[/caption]

Cooling is pretty important to drifting, but it doesn't need to be expensive. I installed a new lower temperature thermostat. What that does is allow the thermostat to open a little sooner and keep the idle temperature of the motor just a little bit lower between runs at the track. This allows me to bag on the car for longer of periods of time with reduced downtime between runs. A cheap $10 mod. The next thing I installed was a higher pressure radiator cap, rather than the 13psi stock one, a 16psi cap was put in it's place. Increasing the cap pressure makes boiling harder for the coolant to do. The greater the pressure contained in the system, the higher the temperature the water will boil at. Boiling is unwanted as it introduces air into the cooling system which doesn't cool nearly as well as the water. You can get caps up to 35psi, but I don't feel like having my coolant hoses explode every 6 laps, or have 35psi of coolant pressure trying to overcome the 34 year old head gasket. Improvements with moderate considerations. The coolant was replaced with water as per track rules, plus it cools better, though doesn't lubricate the water pump as well. I also through in a gauge, as the factory gauges are extremely inaccurate or failed completely.

[caption id="" align="aligncenter" width="1024"]

I'd never seen this before. This thermostat used a rubber seal for the plunger, which had failed, causing the plunger to remain open. I'm glad it never made it to the water pump or into the rest of the system. Poor design choices, feels very German. I installed a slightly lower temp thermostat for long runs at the track.[/caption]

Cooling is pretty important to drifting, but it doesn't need to be expensive. I installed a new lower temperature thermostat. What that does is allow the thermostat to open a little sooner and keep the idle temperature of the motor just a little bit lower between runs at the track. This allows me to bag on the car for longer of periods of time with reduced downtime between runs. A cheap $10 mod. The next thing I installed was a higher pressure radiator cap, rather than the 13psi stock one, a 16psi cap was put in it's place. Increasing the cap pressure makes boiling harder for the coolant to do. The greater the pressure contained in the system, the higher the temperature the water will boil at. Boiling is unwanted as it introduces air into the cooling system which doesn't cool nearly as well as the water. You can get caps up to 35psi, but I don't feel like having my coolant hoses explode every 6 laps, or have 35psi of coolant pressure trying to overcome the 34 year old head gasket. Improvements with moderate considerations. The coolant was replaced with water as per track rules, plus it cools better, though doesn't lubricate the water pump as well. I also through in a gauge, as the factory gauges are extremely inaccurate or failed completely.

[caption id="" align="aligncenter" width="1024"] Never trust your stock temperature gauge!!! Ever! They almost always lie. Keep that car chilling at 190* F (90*C) as that's a dope temp. 210* and some cars start to have miss fires.[/caption]

[caption id="" align="aligncenter" width="576"]

Never trust your stock temperature gauge!!! Ever! They almost always lie. Keep that car chilling at 190* F (90*C) as that's a dope temp. 210* and some cars start to have miss fires.[/caption]

[caption id="" align="aligncenter" width="576"] I tossed a wheel into it as well as it was sitting around and the stock wheel looked to have been chewed by a dog.[/caption]

Next up was the differential. This is a crucial part of a good working drift car. If you're going to a drift day with an open differential or a worn out LSD, you're going to have a bad time. The entire control during a drift, is the speed of the rear wheels and the direction of your steering. These are the primary factors directing the vehicle during a slide. Since we solved the steering angle limitations, it was now time to improve the differential for sliding. Out popped the old, open diff, and the new Locked diff popped in.

What's an open, versus a locked diff? A differential is a mechanical device that divides the power from the engine, delivered by the drive shaft, equally to both rear wheels. The engine only provides one driveshaft, so the differential is there to divide this power so both rear wheels can be powered. There are different types that accomplish this goal different ways. An open differential is found in 99% of all vehicles, it's the cheapest, most reliable and most comfortable design balancing all those factors as best as it can.

I'm not going to reinvent the wheel here. Just watch a video. lol

[embed]https://www.youtube.com/watch?v=gIGvhvOhLHU[/embed]

This video is great. Why's an open differential shitty for drifting? Your ability to control push, and angle during a drift is controlled by the gas pedal. If the rear wheels receive uneven loads/grip of the road, the wheel with the least grip or load will spin much faster than the other. This happens quickly, and unpredictably, which makes controlling the slide very complicated and difficult. Sometimes this can result in a sudden and unexpected spin or even crash!

Limited Slip Differentials are the next most common type of differential found in cars, sometimes called a Posi-trac, or shortened to LSD. These are much better for drifting than an open diff as the wheel speed, and your control of it is much more predictable. However, most older LSD's are worn out and basically operate the same as an open differential. They are costly to rebuild or replace in most cases. Drifting is very hard on LSD's and often wears them out quickly.

I prefer completely Locked differentials, which for daily driving sucks ass, but for drifting is extremely reliable and predictable. Welding open and sometimes LSD differentials is common. Making them into locked differentials. Welded diff's are a hot topic at the track, but it is a tricky type of welding, as the metal is often contaminated by the differential gear oil the diff rests in. It is also difficult to weld, as differentials are usually made using cast steel. Cast requires a lot of heat to penetrate your weld deeply enough to be a long lasting weld.

Another alternative to converting your differential into a locked differential is buying one. Many vehicles have Mini-spools which replace the small spider gears of the open differential, or Full-spools which replace the whole cast unit entirely. These are the most reliable choice of any of the differential options, and luckily enough the second cheapest, only to welding your original diff. LSD's are often $1500+, welded diffs often explode causing a lot of damage, but spools can sometimes be a cheap as $30! I acquired a while back a full spool for my Corolla. People in the Corolla community ignore these and often don't even know they exist for their cars. The mini-spools for E7's are only $40 and work well. The full spools are $150 and will last you a life time.

You can find them easily on here for your Corolla.

Speedway motors $40 8-bolt Toyota mini spool (6.3" S-code diff & early 6.7" T-code)

Speedway motors $150 8-bolt Toyota Full Spool (6.3" S-code & early 6.7" T-code)

Speedway motors $150 10-bolt Toyota Full Spool (Late 6.7" T-code only)

(Note: Early 6.7" -zenki- rear axles used the same spline as the S-code diffs, later 6.7" -kouki- used a larger spline.)

[caption id="" align="aligncenter" width="1024"]

I tossed a wheel into it as well as it was sitting around and the stock wheel looked to have been chewed by a dog.[/caption]

Next up was the differential. This is a crucial part of a good working drift car. If you're going to a drift day with an open differential or a worn out LSD, you're going to have a bad time. The entire control during a drift, is the speed of the rear wheels and the direction of your steering. These are the primary factors directing the vehicle during a slide. Since we solved the steering angle limitations, it was now time to improve the differential for sliding. Out popped the old, open diff, and the new Locked diff popped in.

What's an open, versus a locked diff? A differential is a mechanical device that divides the power from the engine, delivered by the drive shaft, equally to both rear wheels. The engine only provides one driveshaft, so the differential is there to divide this power so both rear wheels can be powered. There are different types that accomplish this goal different ways. An open differential is found in 99% of all vehicles, it's the cheapest, most reliable and most comfortable design balancing all those factors as best as it can.

I'm not going to reinvent the wheel here. Just watch a video. lol

[embed]https://www.youtube.com/watch?v=gIGvhvOhLHU[/embed]

This video is great. Why's an open differential shitty for drifting? Your ability to control push, and angle during a drift is controlled by the gas pedal. If the rear wheels receive uneven loads/grip of the road, the wheel with the least grip or load will spin much faster than the other. This happens quickly, and unpredictably, which makes controlling the slide very complicated and difficult. Sometimes this can result in a sudden and unexpected spin or even crash!

Limited Slip Differentials are the next most common type of differential found in cars, sometimes called a Posi-trac, or shortened to LSD. These are much better for drifting than an open diff as the wheel speed, and your control of it is much more predictable. However, most older LSD's are worn out and basically operate the same as an open differential. They are costly to rebuild or replace in most cases. Drifting is very hard on LSD's and often wears them out quickly.

I prefer completely Locked differentials, which for daily driving sucks ass, but for drifting is extremely reliable and predictable. Welding open and sometimes LSD differentials is common. Making them into locked differentials. Welded diff's are a hot topic at the track, but it is a tricky type of welding, as the metal is often contaminated by the differential gear oil the diff rests in. It is also difficult to weld, as differentials are usually made using cast steel. Cast requires a lot of heat to penetrate your weld deeply enough to be a long lasting weld.

Another alternative to converting your differential into a locked differential is buying one. Many vehicles have Mini-spools which replace the small spider gears of the open differential, or Full-spools which replace the whole cast unit entirely. These are the most reliable choice of any of the differential options, and luckily enough the second cheapest, only to welding your original diff. LSD's are often $1500+, welded diffs often explode causing a lot of damage, but spools can sometimes be a cheap as $30! I acquired a while back a full spool for my Corolla. People in the Corolla community ignore these and often don't even know they exist for their cars. The mini-spools for E7's are only $40 and work well. The full spools are $150 and will last you a life time.

You can find them easily on here for your Corolla.

Speedway motors $40 8-bolt Toyota mini spool (6.3" S-code diff & early 6.7" T-code)

Speedway motors $150 8-bolt Toyota Full Spool (6.3" S-code & early 6.7" T-code)

Speedway motors $150 10-bolt Toyota Full Spool (Late 6.7" T-code only)

(Note: Early 6.7" -zenki- rear axles used the same spline as the S-code diffs, later 6.7" -kouki- used a larger spline.)

[caption id="" align="aligncenter" width="1024"] Full spool on the left, stock open diff on the right. The full spool is much less effort for the engine to spin!!![/caption]

After a few test runs the motor started choking and dying. My plan is to leave the motor and transmission as close to stock as possible. I generally hate the idea of increasing an engines power. The sacrifice is money and reliability always. In order to keep the car going to as many events as possible, it was important to make it run well, but also remain reliable. When it started running poorly I hobbled it over to Joel's house, who is the other half of BCworks. He's a whiz with getting old shitty things running well. Immediately he concluded there was junk in the jets. After carb tear down, and reassembly it was back running stronger than ever! The gas tank hadn't sloshed that hard ever in it's life, so a bunch of old grit had unsettled made it's way past my fuel filter and clogged the jets. I replaced the fuel filter for safe measure. While we were at it, we checked the compression of all the cylinders which was near 160psi across all of them, a healthy little fellow!! Lastly I increased the tension slightly on the transmission kick down cable. In older cars there is a cable that is attached to the throttle, if you tromp the throttle down a certain amount, it will tug the transmission kick down cable. This cable causes the automatic transmission to shift down into a more acceleration oriented gear. By tightening this up a bit, it encourages the engine to wait a little longer before shifting up to longer, top speed gears. This new tension also promotes dropping down into more acceleration oriented gears sooner, which means the transmission is less likely to "shift hunt" during drifts. Drifting can often confuse automatic transmissions as you are constantly changing grip and load on the the tires, as well as your throttle position. The transmission is often confused and jumps back and forth between gears unpredictably. When controlling wheel speed with your throttle these sudden gear changes can massively affect wheel speed and ultimately your control of grip at that moment. Keeping the transmission in one gear improves the predictableness of your throttle control. This is real benefit of a manual transmission, not as much the clutch itself, though helpful.

Some new plugs, fresh oil, and we've caught up to where I'm at with the car right now. In the last 10 days I've put in about 36 hours of work, and I'm ready for a bit of a break from the car for a day or two. However there are still things to touch up before the track day on the 27th. I need a new Distributor O-ring and have a bunch of new suspension to install. I also have to decide if I hate the stickers I fucked up installing on the doors too. I might just leave them, but I wrecked them, and they feel pretty aggressive. However, I already got stopped in the street by a passing motorist to inquire about the car, so they might be more helpful than ugly. lol

[caption id="" align="aligncenter" width="1024"]

Full spool on the left, stock open diff on the right. The full spool is much less effort for the engine to spin!!![/caption]

After a few test runs the motor started choking and dying. My plan is to leave the motor and transmission as close to stock as possible. I generally hate the idea of increasing an engines power. The sacrifice is money and reliability always. In order to keep the car going to as many events as possible, it was important to make it run well, but also remain reliable. When it started running poorly I hobbled it over to Joel's house, who is the other half of BCworks. He's a whiz with getting old shitty things running well. Immediately he concluded there was junk in the jets. After carb tear down, and reassembly it was back running stronger than ever! The gas tank hadn't sloshed that hard ever in it's life, so a bunch of old grit had unsettled made it's way past my fuel filter and clogged the jets. I replaced the fuel filter for safe measure. While we were at it, we checked the compression of all the cylinders which was near 160psi across all of them, a healthy little fellow!! Lastly I increased the tension slightly on the transmission kick down cable. In older cars there is a cable that is attached to the throttle, if you tromp the throttle down a certain amount, it will tug the transmission kick down cable. This cable causes the automatic transmission to shift down into a more acceleration oriented gear. By tightening this up a bit, it encourages the engine to wait a little longer before shifting up to longer, top speed gears. This new tension also promotes dropping down into more acceleration oriented gears sooner, which means the transmission is less likely to "shift hunt" during drifts. Drifting can often confuse automatic transmissions as you are constantly changing grip and load on the the tires, as well as your throttle position. The transmission is often confused and jumps back and forth between gears unpredictably. When controlling wheel speed with your throttle these sudden gear changes can massively affect wheel speed and ultimately your control of grip at that moment. Keeping the transmission in one gear improves the predictableness of your throttle control. This is real benefit of a manual transmission, not as much the clutch itself, though helpful.

Some new plugs, fresh oil, and we've caught up to where I'm at with the car right now. In the last 10 days I've put in about 36 hours of work, and I'm ready for a bit of a break from the car for a day or two. However there are still things to touch up before the track day on the 27th. I need a new Distributor O-ring and have a bunch of new suspension to install. I also have to decide if I hate the stickers I fucked up installing on the doors too. I might just leave them, but I wrecked them, and they feel pretty aggressive. However, I already got stopped in the street by a passing motorist to inquire about the car, so they might be more helpful than ugly. lol

[caption id="" align="aligncenter" width="1024"] Managed to score a Snell approved open face, almost new for $80! I'm stoked.[/caption]

[caption id="" align="aligncenter" width="711"]

Managed to score a Snell approved open face, almost new for $80! I'm stoked.[/caption]

[caption id="" align="aligncenter" width="711"] I picked up these front coils, not pictured is the KYB shock and TRD spring combo I also acquired for the rear. Sadly the hubs are slightly bent on these, and they're AE86 brake bolt pattern, so I'll be chopping the strut tubes in the middle and welding them onto the proper E7 hubs. Won't be done for the practice day.[/caption]

So let's figure this out, roughly speaking, my bank account has seen a loss of about $1200 to build this car so far. It's not quite done yet, but it's closer than it was before I started. This car will probably drift okay. It won't be the worlds best, it's probably kinda suck, but that's why other people will be allowed to use it. There's still more work to go. Below is a rough cost structure of the things that went into the car, minus fluids, insurance and government costs, mid night snacks, and other things. I'm fucking broke now. It took me 2 years to save up that much dough, but hopefully others learning will feel really rewarding for me.

Purchase Price $400

Transmission cooler fittings $25.88

Tie rod sleeves, 38.06

Fuel filter 9.08

Oil filter 12.44

Plugs 11.52

Fuel Pump 30.28

Transmission cooler lines $8.19

Clamps 4.08

Suspension $120

Knuckles and LCA's $50

Tuning $3.09

Stickers $20

Helmet $80

Gauge $10

$822.62 Approximately.

Don't forget the thank yous!

Purchase of the car (Thanks to Gwendolyn!)

Rear Speedway motors full spool (Thanks Colby & Brian!)

Full suspension, front T3 coilover with 7kg springs, KYB shocks front and rear, with mystery rear TRD springs (Thanks Jason!)

BC works shortened and reduced ackerman knuckles, and lengthened LCA's (Thanks Warren!)

Mechanical Temp Gauge (Thanks Nick!)

Transmission oil cooler (Thanks Potato Dave!)

Grant Steering wheel and hub (Thanks Corey!)

Set of 4 dope 13"s (Thanks Eric!)

Temperature gauge sender (Thanks Nick and Haley!)

Suspension acquisition (Thanks Brett and Andrew!)

Garage space, few tools (Thanks Dugan!)

Engine troubleshooting (Thanks Joel!)

Last Minute stickers (Thanks Trevor!)

Fuck, I'm sure there are others. I've just been typing for 2 hours and brain dead.

Right, current pics. Good way to end this installment of the ghetto school car.

I picked up these front coils, not pictured is the KYB shock and TRD spring combo I also acquired for the rear. Sadly the hubs are slightly bent on these, and they're AE86 brake bolt pattern, so I'll be chopping the strut tubes in the middle and welding them onto the proper E7 hubs. Won't be done for the practice day.[/caption]

So let's figure this out, roughly speaking, my bank account has seen a loss of about $1200 to build this car so far. It's not quite done yet, but it's closer than it was before I started. This car will probably drift okay. It won't be the worlds best, it's probably kinda suck, but that's why other people will be allowed to use it. There's still more work to go. Below is a rough cost structure of the things that went into the car, minus fluids, insurance and government costs, mid night snacks, and other things. I'm fucking broke now. It took me 2 years to save up that much dough, but hopefully others learning will feel really rewarding for me.

Purchase Price $400

Transmission cooler fittings $25.88

Tie rod sleeves, 38.06

Fuel filter 9.08

Oil filter 12.44

Plugs 11.52

Fuel Pump 30.28

Transmission cooler lines $8.19

Clamps 4.08

Suspension $120

Knuckles and LCA's $50

Tuning $3.09

Stickers $20

Helmet $80

Gauge $10

$822.62 Approximately.

Don't forget the thank yous!

Purchase of the car (Thanks to Gwendolyn!)

Rear Speedway motors full spool (Thanks Colby & Brian!)

Full suspension, front T3 coilover with 7kg springs, KYB shocks front and rear, with mystery rear TRD springs (Thanks Jason!)

BC works shortened and reduced ackerman knuckles, and lengthened LCA's (Thanks Warren!)

Mechanical Temp Gauge (Thanks Nick!)

Transmission oil cooler (Thanks Potato Dave!)

Grant Steering wheel and hub (Thanks Corey!)

Set of 4 dope 13"s (Thanks Eric!)

Temperature gauge sender (Thanks Nick and Haley!)

Suspension acquisition (Thanks Brett and Andrew!)

Garage space, few tools (Thanks Dugan!)